A Whole Lot of Structural Integrity Tools

Wendy Laursen

November 6, 2025

Aker BP is already using AI to shape the future of its subsea infrastructure integrity management. The company plans to more than double its subsea infrastructure by 2027 and is moving toward a new operational paradigm.

“Our vision is to deliver world-class operational performance with high production efficiency, low environmental discharges, and low costs,” says Camilla Leon, VP Subsea, Aker BP. “We believe we can achieve this by liberating and sharing data, applying automation and advanced analytics, and building a common situational awareness across our ecosystem of partners and internal stakeholders.”

Leon is a board member of Elementz, a software-as-a-service company that is supporting that vision with its integrity management software. Elementz CEO, Jason Brown, says structural integrity and inspection is undergoing a fundamental transformation, moving from traditional time-based strategies to data-driven approaches. This evolution is being accelerated by advances in real-time monitoring, autonomous inspection, and predictive analytics.

For Elementz, the change is best understood through the lens of its Blue Digital Ecosystem, an interconnected digital infrastructure where data, systems, and stakeholders work seamlessly together. “Integrity is no longer an isolated discipline,” says Brown. “It is becoming an intelligent, always-on layer that connects inspection gathering technologies, asset data, and decision-making across the entire subsea value chain.”

He says the future of structural integrity will include interconnected digital twins sharing intelligence across operators and assets, including applying insights from oil and gas to renewables.

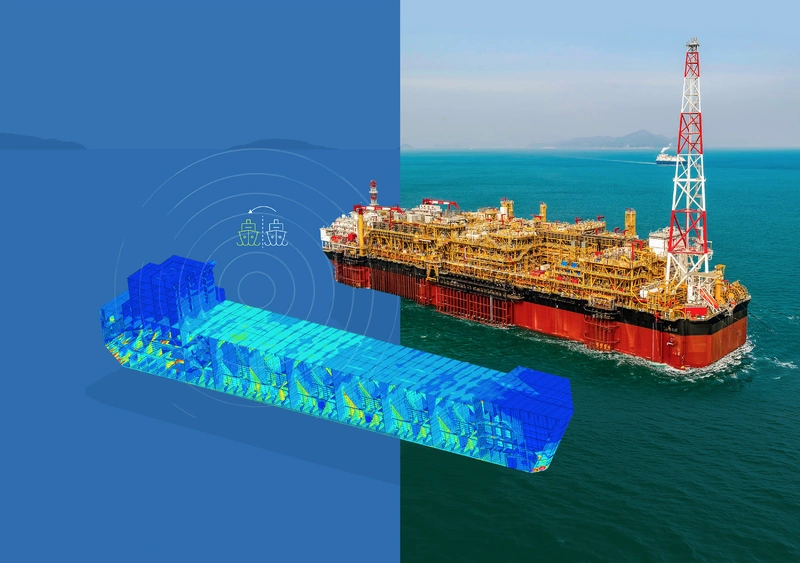

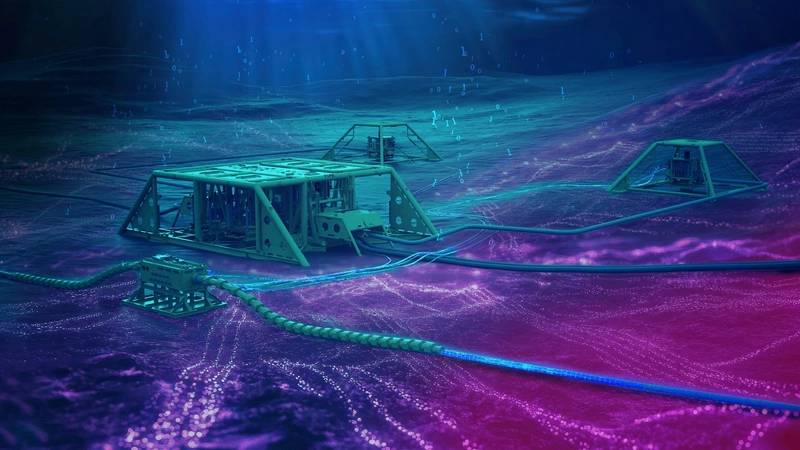

Structural integrity and inspection is moving from traditional time-based strategies to data-driven approaches. Image courtesy of Elementz

Structural integrity and inspection is moving from traditional time-based strategies to data-driven approaches. Image courtesy of Elementz

Asset integrity is becoming an intelligent, always-on layer that connects inspection gathering technologies, asset data, and decision-making across the entire subsea value chain. Image courtesy of Elementz

Asset integrity is becoming an intelligent, always-on layer that connects inspection gathering technologies, asset data, and decision-making across the entire subsea value chain. Image courtesy of Elementz

The next wave of technologies is already reshaping structural integrity management with digital twins that mirror real-time structural conditions and allow simulation of fatigue, stress, and extreme events. IoT and structural health monitoring systems continuously capture vibration, strain, and motion data; fleets of drones, ROVs, AUVs, and climbing robots conduct routine inspections; and AI-driven analytics optimize inspection schedules and predict failures before they occur.

Light Structures is expanding the scope of its structural health monitoring system to include jack-up rigs as well as FPSOs and offshore wind platforms. Mobile drilling platforms present a distinct set of structural risks, as they face uneven leg loading during jacking, variable soil conditions that affect stability, and fatigue at the leg-hull interface, all within a structure with safety margins that can shift quickly depending on water depth and seabed behavior. Traditional inspection regimes struggle to account for these dynamic factors, especially during preloading or storm conditions when structural loads can peak.

The Light Structures system involves installing fiber optic sensors in each jacking house. These sensors measure the strain in the structural members that transfer loads into the legs. The system then converts these readings into sectional loads and stress values using a digital twin that adjusts for operational conditions like water depth and seabed stiffness. This provides real-time feedback on leg balance, structural stress, and proximity to critical limits, which enables operators to intervene early if asymmetry develops or a leg becomes overloaded.

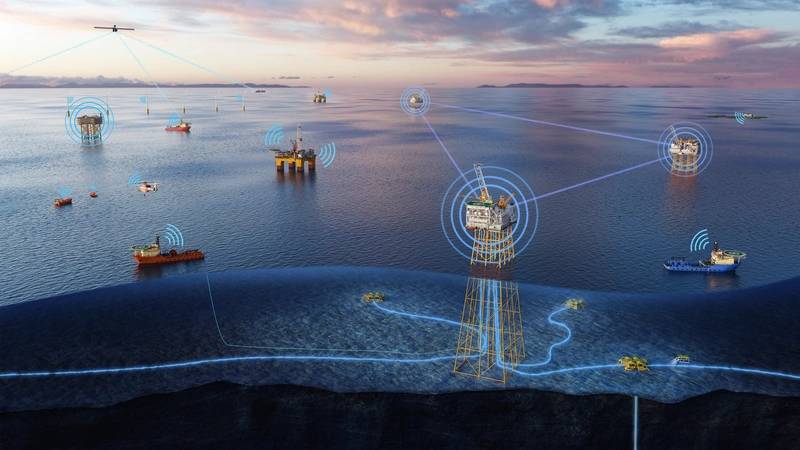

Operators now view private networks as critical infrastructure for enhancing connected workers, digital workflows, improving safety, and enabling advanced automation. Image courtesy of Tampnet

One of the system’s advantages is its ability to shift operators from calendar-based maintenance to condition-based strategies. When a rig experiences a storm, a difficult jacking sequence, or preloading operations, the system captures exactly where and how hard the structure was worked. This allows inspections to be targeted and justified, avoiding unnecessary downtime while still addressing risk. Over time, this also supports more accurate life-extension decisions based on actual fatigue data.

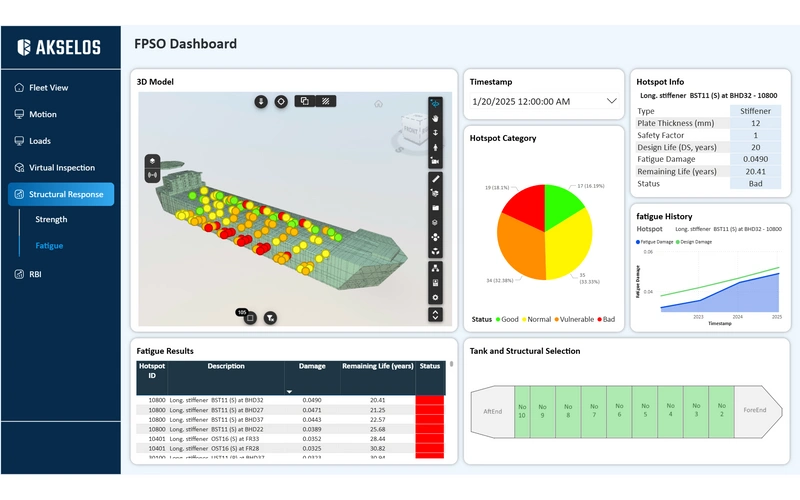

Akselos’ SPM software is also being used for life-extension analysis. The system changes the scale of sensor and strain gauge monitoring by providing a high-fidelity, near real-time structural twin of an entire FPSO. This has been made possible by a new, faster patented RB-FEA calculation method the company developed. By combining inspection records, metocean conditions, and cargo operations into one dynamic model, operators gain a live, continuous view of structural performance. This allows for real-time monitoring, identification of stress concentrations, and on-demand fatigue analysis to support data-driven maintenance and risk-based inspections.

Dr. Claus Reimers, Chief Product and Technology Officer at Akselos, cites the case where the Bonga FPSO was close to end-of-life. “They could not model the whole structure in one go, so they made very conservative assumptions. That could have meant retiring the asset way too early. For Bonga, we helped them unlock a significant life extension.”

Amine Boumnijel, Product Owner for Offshore Structures at Akselos, explains that during the design phase, many assumptions are made about how an asset will be operated and the environment it will face, which can differ significantly from actual operating conditions. So, conservative safety margins are built into the design, forming the basis for class-required, fixed-interval inspection plans. This can lead to over-inspection in areas that may not be at real risk, while potentially overlooking emerging issues in other critical locations.

“We reduce all of these unknowns by using the actual data including the continuous wave acquisition data from wave radars, or any available up-to-date data. We also update the structure thickness from inspections or maintenance reports. So, we can represent the whole FPSO as it is right now, not as the early assumptions of the design would portray it, which unlocks really huge value for inspection and for life extension.”

Akselos has developed a new, faster patented RB-FEA calculation method. Image courtesy Akselos

Akselos has developed a new, faster patented RB-FEA calculation method. Image courtesy Akselos

Provider of offshore high-capacity, low-latency connectivity solutions, Tampnet, is ushering a new level of communication support for the industry’s digital transformation with the recent deployment of a Private Multi-Access Edge Compute (PMEC) with 4G/5G capabilities on Vår Energi's Jotun FPSO. This full wireless coverage is part of Vår Energi's Digital Field Worker program which is improving safety, efficiency, and data quality by connecting field workers on offshore installations with digital applications covering 80% of tasks performed.

Tampnet's solution at Jotun includes dedicated cellular coverage, local compute power, and secure private network capabilities to support real-time communication, predictive maintenance, edge AI, and remote assistance.

The offshore PMEC market has rapidly evolved from pilot projects to large-scale adoption, says Chief Architect Øyvind Skjervik. Operators now view private networks as critical infrastructure for enhancing connected workers, digital workflows, improving safety, and enabling advanced automation. Tampnet currently supports private mobile networks on 20 offshore rigs and has secured orders for an additional 30 rigs and platforms.

Skjervik says PMEC technology serves as the foundation for the next generation of offshore operations. As well as providing real-time digital twins and predictive analytics, it will reduce human risk by enabling autonomous inspections and robotics and facilitate real-time hazard detection for those still working offshore.